Composite timber furniture refers to furniture pieces made from engineered or manufactured wood products rather than solid natural timber. These composites are created by bonding wood fibers, particles, or veneers together with adhesives under heat and pressure.

Common composite timber materials include:

- Plywood – Thin wood veneers glued in alternating grain directions for added strength and stability.

- Particleboard – Made from wood chips and resin; affordable but less durable.

- Laminated veneer lumber (LVL) – Thin wood layers bonded together for enhanced strength and consistency.

- HDF (High-Density Fiberboard) – Denser and stronger than MDF, providing a smooth and durable surface.

Benefits:

- Cost-effective : Provides an economical alternative to solid wood.

- Stable and Durable : Less prone to warping, cracking, or shrinking.

- Design Flexibility : Available in large sheets for seamless and creative designs.

- Compatible Finishes : Compatible with laminates, veneers and various paint finishes.

Production Process :

1.Material Selection & Cutting.

Composite boards (MDF, plywood, etc.) are selected based on strength, finish and intended use. CNC machines or panel saws are used to cut the sheets to precise dimensions.

2. Edge Banding

Edges are sealed with PVC, ABS, or wood veneer strips using edge-banding machines to enhance durability and aesthetics.

3. Surface Treatment

Surfaces may be:

- Laminated with decorative layers,

- Painted,

- Veneered with natural wood, or

- Coated with melamine for improved moisture resistance

4. Assembly

Components are joined using dowels, cam locks, screws or adhesives. Flat-pack methods are commonly used for efficient mass production.

5. Finishing

Final finishes such as lacquering, polishing or matte coating are applied to protect the surface and enhance appearance.

Fitting and Installation

Common fitting processes include:

Flat Pack Assembly:

Furniture components are pre-drilled and labeled for easy assembly by customers or technicians using the provided hardware.

Built-in Units:

For kitchens, wardrobes, or office furniture, fitting involves:

- Measuring and leveling the walls,

- Securing base and wall cabinets with brackets or screws,

- Joining units with connector bolts or dowels and

- Finishing with trims, fillers or custom panels for a seamless look.

On-Site Adjustments:

Final adjustments may include trimming, aligning doors or drawers, and installing fixtures such as handles and hinges.

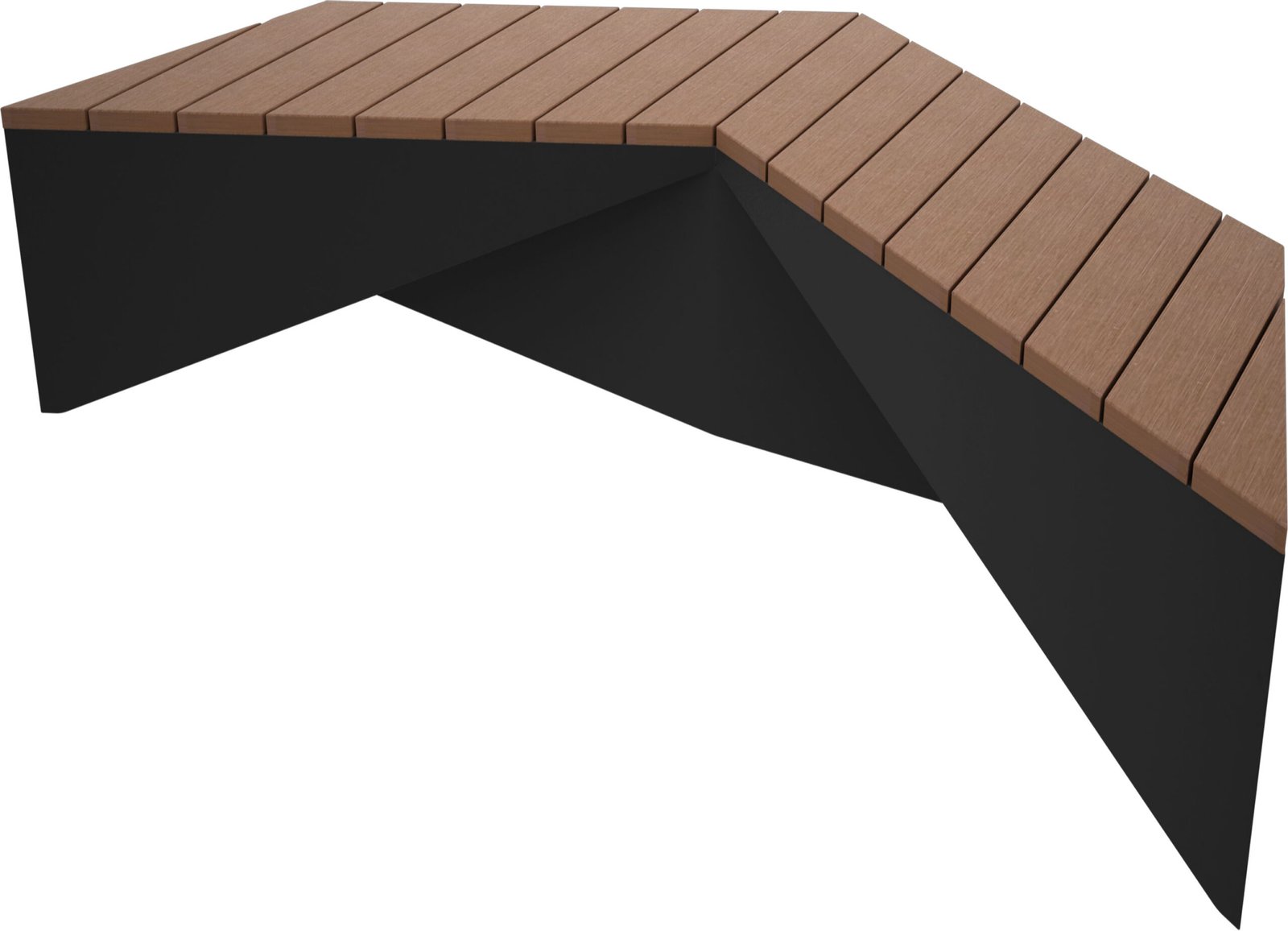

Photo Gallery